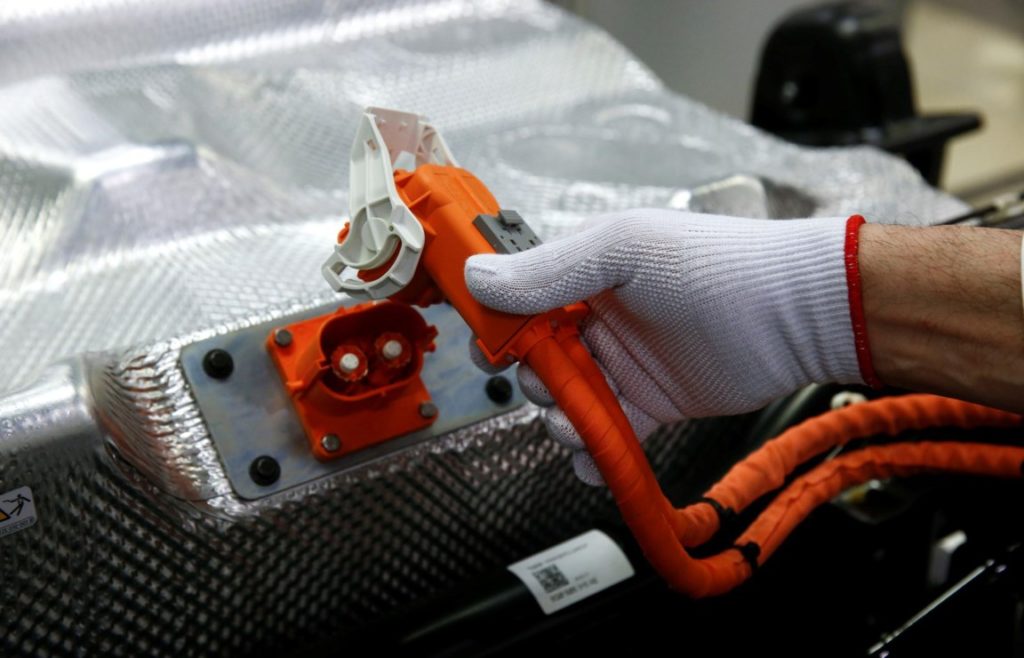

German carmaker BMW has created a vehicle battery recycling venture with Belgian materials and recycling firm Umicore and the Swedish company, Northvolt. According to some environmental organisations, the electric car, which does not emit CO2, is less environmentally friendly than it seems. This is because the production process for the battery pollutes and the battery produces waste that is difficult to recycle. The German car maker BMW now wants to address this weakness by entering into a technological partnership with the battery producer Northvolt (co-founded by a former top director at Tesla) and Umicore.

The three partners aim for a closed cycle for the battery. This involves five facets.

1. A battery design that allows as much recycling as possible

2. A production process that uses as much renewable energy as possible

3. An extended life for the battery in the car

4. A second life for the car battery, for example as a battery for home for energy storage

5. A recycling of battery

Umicore will play a role in two areas: the supply of materials for batteries and recycling at the end of the chain. Although it is still too early to discuss possible contracts, the focus will be on research. “This is not a commercial alliance, but a technological alliance,” emphasises a company spokesperson.

In its recycling venture with Northvolt and Umicore, BMW said it had made an initial investment of an undisclosed amount and would provide its expertise in battery cell development.

Umicore announced in June that it would build a new battery technology plant in Nysa, Poland, rather than on the former Opel site in Antwerp, which some had hoped for. The new site, which will be located near numerous battery plants, will play an important role in the technology alliance with BMW. Nysa is only a three hour drive from the Leipzig factory where the electric BMW i3 is produced.

The Belgian materials company does not produce batteries itself. It supplies active anode and cathode materials, which are crucial components to battery producers. A battery consists of an anode and a cathode - the negative and the positive pole - and the moving electrons between the two create energy. Umicore makes alloys for cathodes based on nickel, manganese and cobalt.

“This underlines the future potential and importance of a European supply chain for the success of automotive electrification in the region," said Umicore CEO Marc Grynberg in a joint communique.

The German-Swedish-Belgian consortium is also a boost for the European Commission. A year ago it brought together major European companies, including the Belgian leaders in the field, Umicore and Solvay, with one goal: to catch up in the production of batteries for electric cars, a market dominated by Asian players.

BMW, which has supply deals with Samsung and CATL, said it could source batteries from Northvolt in the future but said it was too early to sign any deal with the firm, which is building a plant that aims to produce 32 gigawatt hours (GWh) of battery capacity a year by 2023.

This “battery alliance” is now being given its first exponent. Commissioner Maros Sefcovic, responsible for energy efficiency, welcomed the BMW initiative.

Arthur Rubinstein

The Brussels Times